Steel is a versatile and durable material that has been used in construction for centuries. Steel buildings are popular for their strength, durability, and cost-effectiveness. But have you ever wondered how steel buildings are manufactured from raw materials into the finished product that we see on construction sites?

In this article, we will take a closer look at the steel building manufacturing process and the steps involved in transforming raw materials into the finished steel building product.

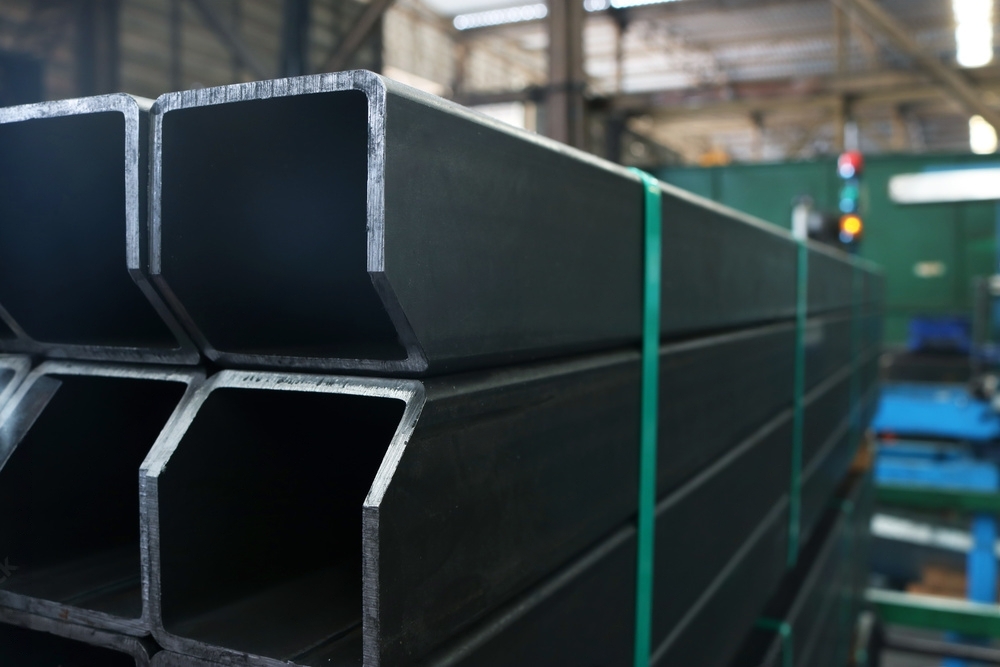

Step 1: Raw Materials

The first step in the steel building manufacturing process is the sourcing of raw materials. The raw materials used in the manufacturing of steel buildings are primarily steel sheets and structural steel shapes. These raw materials are sourced from steel mills, steel service centers, or directly from steel manufacturers.

Step 2: Design and Engineering

Once the raw materials have been sourced, the next step is the design and engineering of the steel building. This step involves creating a detailed blueprint of the building, including the dimensions, layout, and structural components. The design and engineering process also includes the calculation of the loads and stresses that the building will need to withstand.

Step 3: Fabrication

After the design and engineering process, the raw materials are sent to the fabrication shop. In the fabrication shop, the steel sheets and structural steel shapes are cut, drilled, and welded together to create the various components of the steel building. The fabrication process involves using specialized equipment, such as plasma cutters, welding machines, and CNC machines, to shape the steel components to the exact specifications of the building design.

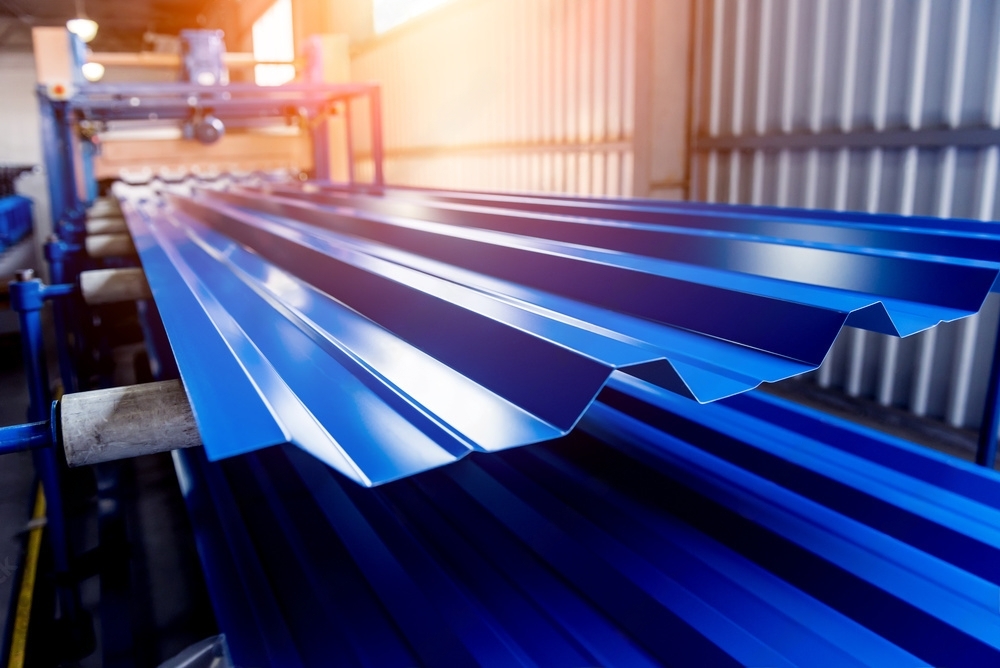

Step 4: Coating

Once the steel components have been fabricated, they are sent to the coating facility. In the coating facility, the steel components are cleaned, primed, and painted to protect them from corrosion and other environmental factors. The coating process involves using specialized equipment, such as spray guns and electrostatic sprayers, to apply the primer and paint coatings to the steel components.

Step 5: Assembly

After the coating process, the steel components are sent to the construction site for assembly. The assembly process involves using cranes and other heavy equipment to lift and position the steel components into place. The steel components are then bolted or welded together to create the final steel building structure.

Step 6: Finishing

Once the steel building structure has been assembled, the finishing touches are added to complete the building. This may include the installation of doors, windows, and other fixtures, as well as the application of interior and exterior finishes.

In conclusion, the steel building manufacturing process involves a series of complex steps, from sourcing raw materials to the final assembly and finishing of the building. The process requires specialized knowledge, equipment, and expertise, and is carried out by skilled professionals in the steel fabrication industry. The end result is a durable and long-lasting steel building that provides a strong and reliable structure for a wide range of applications.

Another topics to take in mind are:

Quality Control

Quality control is an important aspect of the steel building manufacturing process. Quality control measures are put in place at every step of the process to ensure that the steel components meet the required standards and specifications. Quality control measures include visual inspections, testing, and documentation of the manufacturing process.

Sustainability

Sustainability is also an important consideration in the steel building manufacturing process. Steel is a recyclable material, and many steel buildings are made with recycled steel. Additionally, the coatings used in the manufacturing process are often environmentally friendly and contain low levels of volatile organic compounds (VOCs).

Customization

Steel buildings can be customized to meet the specific needs and requirements of the customer. The design and engineering process allows for flexibility in the size, shape, and layout of the building, as well as the addition of various features such as doors, windows, and insulation.

Uses

Steel buildings have a wide range of uses, from commercial and industrial buildings to agricultural and residential structures. They are commonly used for warehouses, factories, retail spaces, and office buildings. Steel buildings are also popular for agricultural purposes, such as barns, storage sheds, and livestock shelters.

In conclusion, the steel building manufacturing process is a complex and multi-step process that requires specialized knowledge, equipment, and expertise. The process involves sourcing raw materials, designing and engineering the building, fabricating the steel components, coating the components, assembling the building structure, and finishing the building. Quality control, sustainability, customization, and various uses are all important aspects of the steel building manufacturing process. Steel buildings provide a durable and long-lasting solution for a wide range of applications.